SPECTRAL ENERGY SAVING

product package

SPECTRAL ENERGY SAVING is a range of refinishing products designed for modern workshops looking to significantly reduce operating costs, shorten work time, and lower energy consumption – all without compromising repair quality.

Thanks to innovative low-temperature curing technologies and fast drying times, this product line delivers maximum process efficiency even at reduced spray booth temperatures – directly translating into real savings.

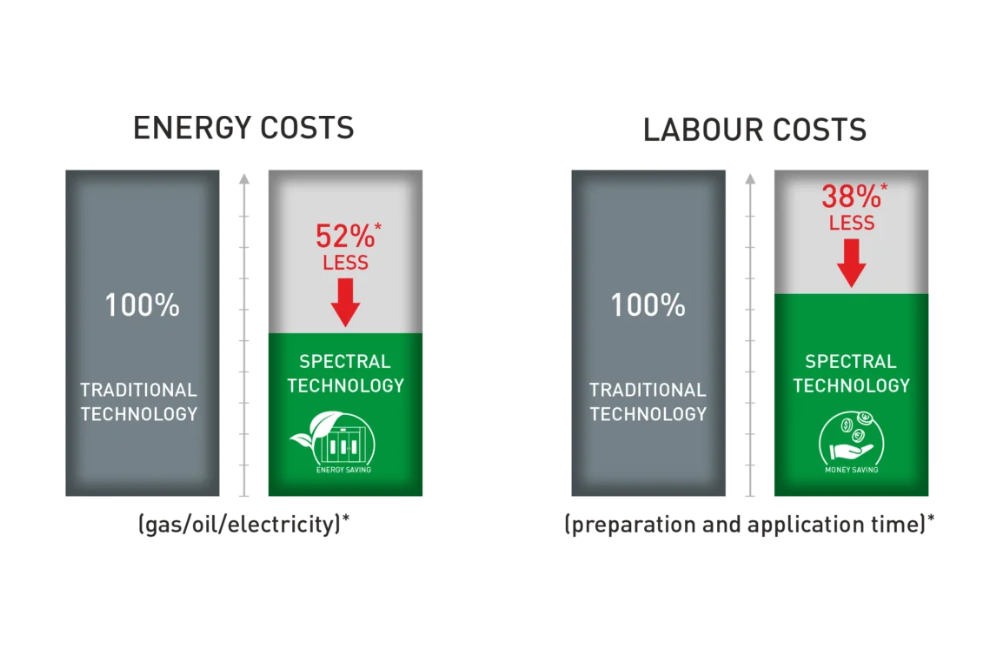

Save up to 52% on energy costs with high-efficiency, fast-performing SPECTRAL products!

SAVING ENERGY

- lower heat curing temperatures

- extremely short heat curing times

- products designed for application and drying already at low temperatures

SAVING LABOUR TIME

- faster application by reducing the flash-off time

- products that do not require sanding for up to 12h after the application

- can be applied wet-on-wet

The SPECTRAL ENERGY SAVING product package means tangible benefits to your refinishing operation.

It does not matter whether your shop repairs 25 or 100 vehicles a month. Using SPECTRAL products every month, you can enjoy significantly lower cost for each repair job!

You can save up as much as nearly 18,000 euros on energy consumption and labour a year!

Start saving today!

SPECTRAL ENERGY SAVING package products

See the products in the SPECTRAL ENERGY SAVING package selected specially for you. Use them to slash your repair costs by a big number!

KLAR 545-00

Energy-efficient VHS acrylic clearcoat

- extremely short heat curing time: 15 min

- heat curing time temperature reduced to 40°C

- lower costs of heat curing in spray booths: down by 52%

- very high yield: VHS (very high solids content)

- suitable for spot and full body repairs

- ensures quick and easy application

- perfect for recoating of hybrids and EVs

- very high gloss level

Watch the demonstration video

KLAR 545-00

UNDER 385-00

Isolating anti-corrosion epoxy primer

- excellent anti-corrosion and insulation performance

- coatable with polyester putties already in 30min @ 20°C

- olive tint to ensure OEM-specific appearance

- requires no sanding up to 12 h @ 20°C

- perfect flow – can be applied wet-on-wet under decorative coating layers

- long pot life

- excellent adhesion to most plastics when using PLAST 825

- can be applied on e-coated parts

Watch the demonstration video

UNDER 385-00

UNDER 00-RACE

Aspartic filler

- curing time down by as much as 70% versus traditional fillers

- sandable already in only 20 minutes without heat curing

- application time reduced by 50% – 0 to 5 min of flash-off time between layers

- can be applied already at 10°C

- smooth surface finish

- very high yield: lower filler consumption

Watch the demonstration video

UNDER 00-RACE

UNDER 375-00

High build AIR DRY filler

- helps save the energy media required to accelerate the drying of traditional fillers

- short time to sand (60 to 90 min./20°C) depending on the number of layers (1 to 3)

- designed for drying already at low temperatures (down to 5°C)

- high build acrylic filler

- can be applied in very thick layers

- can be applied without prior sanding of OEM e-coated parts

- excellent dry power sanding

- perfect for filling scratches and roughness

- spectral grey system

SPECTRAL WAVE 2.0

An innovative water-based coating system

- one of the fastest water-based basecoat systems

- system components only need stirring by vigorous hand shaking, directly before use

- convenient disposable containers

- made with the latest water-soluble dispersions

- tens of thousands of colours in ready to use recipes with an infinite palette of custom colour combinations

- highly stable components

- small and compact heated rack for easy placement in the paint shop

- excellent hiding power

- excellent drying

- easy application and fading out

- suitable for single-layer coating systems for vehicle interiors and exteriors

Polski

Polski  Русский

Русский  Deutsch

Deutsch  Español

Español  Français

Français  Українська

Українська  Ελληνικά

Ελληνικά