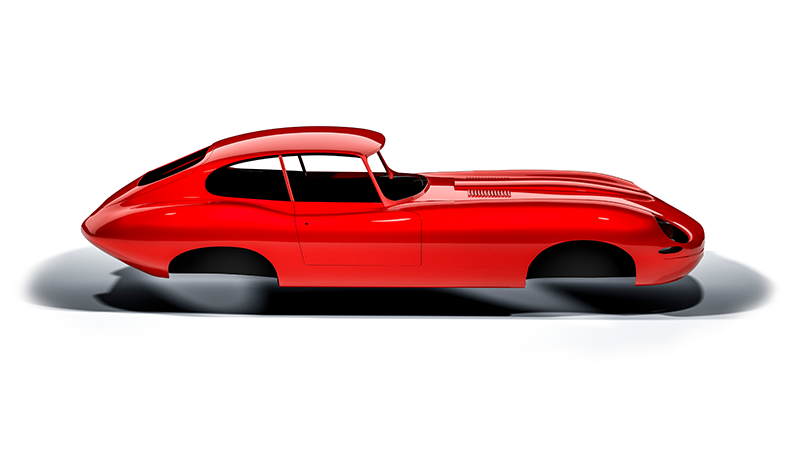

Thorough stripping of old paint coats from bodywork and chassis components of oldtimer cars is key in the vehicle renovation processes.

There are currently several options and technologies available for the removal of old coatings. Here is a summary of the available technologies with their pros and cons:

- Sand blasting: this term can be misleading, as it suggests that sand is the only abrasive medium available – but there are other types of abrasive grit in bulk used for blasting, like corundum (aluminium oxide), copper smelting slag, and nut shells. Each abrasive medium has a unique abrasive strength and performance. However, the poor application of these materials can deform the surface. This type of process is most recommended for confined locations with internal bracing, such as the edges of the bodywork. It is not advised to sand blast the panelwork itself, unless using one of the latest synthetic abrasive media, such as plastic grit. Plastic grit, in the form of fine balls, carries a low risk of bodywork damage, while maintaining a very high level of coat stripping performance.

- Glass bead peening: a less invasive abrasive blasting medium, which is excellent for stripping coats from small workpieces as well as whole assemblies. Here the abrasive is fine beads of glass, which can be used to gently remove decorative finish coats.

- Soda blasting: this is one of the latest abrasive processes, and is growing in popularity. The abrasive is based on baking soda with a specific grain size. While it is very mild to the base material, it has a low efficiency in stripping hard coatings, meaning that reprocessing may be required. One risk of this type of processing is the soda residues left on the base material prior to recoating. It is best to thoroughly wash soda-blasted workpieces before recoating.

- Chemical stripping: this is the most complex of all coat stripping processes; however, it is the most efficient and the safest for old components. It involves professional stripping chemicals in tanks, into which the workpieces are dipped. Chemical stripping perfectly cleans workpieces of old coatings and, once the chemicals have been neutralized, leaves the workpiece surfaces perfectly ready for downstream refinishing processes.

- Pyrolysis: a process well known in other industries, and involves the stripping of old coats at high temperatures. A vehicle so processed requires the removal of all synthetic and plastic parts, prior to being moved to a pyrolytic stripping oven. Here it is kept at very high temperatures, but under the steel deformation point.

Mechanical or power stripping: this is the most common removal method for old coats. It provides the best control over the stripping process, although it is most time intensive. The coats are removed using power strippers, and abrasive paper and plastic pads.

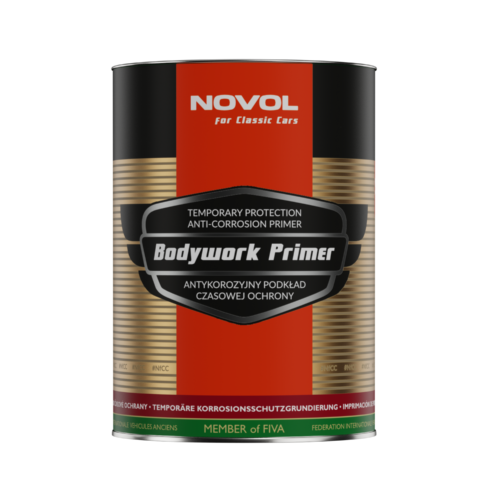

Temporary protection anti-corrosion primer

The latest generation in bodywork primers for anti-corrosion protection during bodywork repairs after removal of the old coating. The corrosion inhibitors provide at least 6 months of protection after the application.

The water-based resins allow easy fusion or pressure welding of metals primed with the product (72 h after application).

Bodywork Primer is designed to require cleaning only the bodywork locations repaired by fusion/pressure welding after the product application, followed by degreasing twice with SILICONE REMOVER, and the application of EPOXY PRIMER.

PROPERTIES:

- Up to 6 months of anti-corrosion protection

- Primed workpieces can be pressure or fusion-welded

- No sanding to matt required before the application of epoxy primers

- No stripping away required before the downstream refinishing steps

- The contrasting, claret colour of the primer makes it easy to evaluate the hiding power in confined areas of workpieces

- Very high yield

BODYWORK PRIMER

Protection during bodywork

72 h / 20°C

SILICONE REMOVER

Universal degreaser

EPOXY PRIMER

Anti-corrosion, epoxy – thick-layered

24 h / 20°C

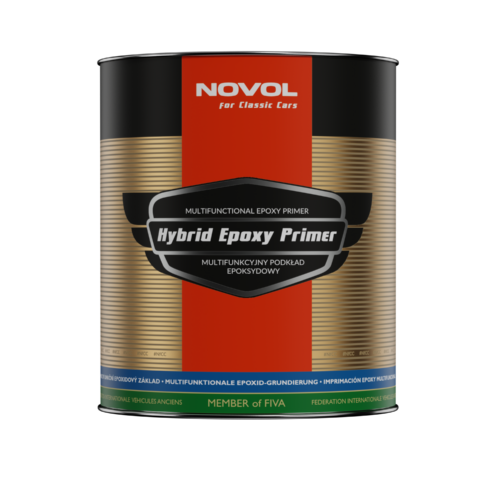

Anti-Corrosion Epoxy Primer

The latest generation in VHS epoxy primers, the product features additional corrosion inhibitors for dual anti-corrosion protection: anti-corrosion barrier and protection.

A specially selected composition of epoxy resins and ball-ground mineral fillers provides a very smooth surface in cream beige with a subdued glow to improve the identification of locations which require sculpting.

The EPOXY PRIMER provides proper double-action protection of surfaces left highly porous after sandblasting or power stripping, with a texture resulting in different layer builds, where a barrier formula might not be sufficient.

PROPERTIES:

- Excellent anti-corrosion performance (barrier and protection in one)

- Suitable for high-build layers

- Suitable for application on very coarse substrates, including abrasive-blasted steel

- Perfect levelling

- Very good penetration for excellent adhesion to metal surfaces

- Very high chemical resistance and mechanical strength

Can be applied on e-coats without prior sanding

EPOXY PRIMER

Anti-corrosion, epoxy – thick-layered

24 h / 20°C

Lightweight Multifunctional Body Filler

A multifunctional body filler with carefully selected lightweight fillers and resin that provide great convenience when sculpting bodywork parts. If applied to large work areas in large mixed batches, it is critical to thoroughly mix the polyester resins with the hardener. Otherwise, the decorative paint coat might become discoloured and require refinishing.

Blue Light features the unique Mixing Indicator technology, which shows the polymerisation ratio.

The Mixing Indicator is a visual reference for your assessment of how thoroughly the filler has been mixed with the hardener to avoid component mixing ratio errors. The filler is originally blue, and when mixed with the hardener the colour shifts to grey, and then, when polymerisation ends, the final colour is light beige.

It is natural for polyester fillers to exhibit sedimentation coupled with surfacing of a part of the resin and the dye. It is perfectly normal and common to this type of product. It is always necessary to homogenize the product by stirring it in the container before mixing with the hardener.

PROPERTIES:

- Very easy rough and finish processing

- Perfect for sculpting shapes on large work areas

- The safe Mixing Indicator technology ensures perfect mixing of the components

- Creamy texture for easy application

- Very low volumetric shrinkage, thanks to spherical fillers

BLUE LIGHT

Light and multi-functional

30 min / 20°C

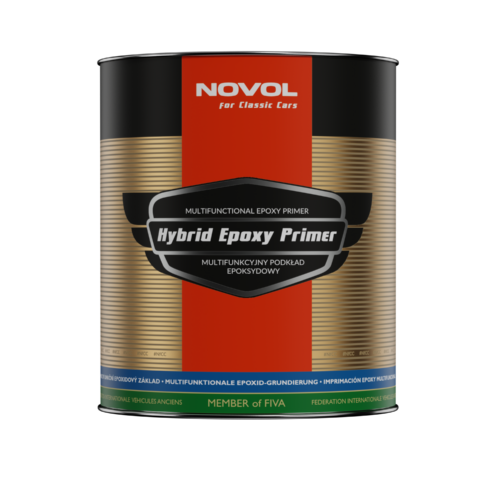

Insulation performance: HYBRID EPOXY PRIMER + HYBRID ISOLATOR HARDENER

HYBRID EPOXY PRIMER with HYBRID ISOLATOR HARDENER is intended for preservation of metal substrates, on which the combination forms a sealed coating with high anti-corrosive performance.

The thin-coat primer protects against the absorption of solvents and potential moisture during pretreatment prior to the application of decorative coatings. This product is recommended for the entire refinishing process when isolating over-sanded spots (exposing bare metal). It is suitable for wet-on-wet application.

PROPERTIES:

- Quick-drying epoxy primer

- Perfect for anti-corrosion protection and isolation of spots sanded to bare metal

- Excellent protection against thinners and moisture

- Very smooth texture for easy wet-on-wet application

HYBRID EPOXY PRIMER

Innovative combination of the features of epoxy and acrylic primer

ANTI-COROSION / ISOLATOR / FILLER

HYBRID ISOLATOR HARDENER

Hardener for HYBRID EPOXY PRIMER

Spray filler

A polyester spray filler with the colour-shift based Mixing Indicator for the polymerisation ratio. The P-S spray filler is a finish filler for the final stage of surface sculpting.

The filler reduces sagging and isolates earlier layers of a filler mixed with the hardener at an incorrect ratio. The special selection of fillers and resins minimises shrinkage to 5%, providing excellent processability on large work areas. Further processing of the product’s layer is recommended after a minimum of 12–16 h at 20°C.

The Mixing Indicator is a visual reference for your assessment of how thoroughly the filler is mixed with the hardener to avoid component mixing ratio errors. The filler is originally sharp blue, then when mixed with the hardener the colour shifts to grey blue and, when polymerisation ends, the final colour is white.

It is natural for polyester fillers to exhibit sedimentation coupled with surfacing of a part of the resin and the dye. It is perfectly normal and common to this type of product. It is always necessary to homogenize the product by stirring it in the container before mixing with the hardener.

PROPERTIES:

- Produces a smooth surface on large work areas

- Easy and quick application from a Ø2.5 mm spray gun

- Safe to apply in thick layers (up to 300 µm) without sagging

- The Mixing Indicator becomes active already during mixing, ensuring good assessment of correct component blending

- Can be thinned further (up to 10% vol.)

P-S

Spray for final sculpting of work surfaces

3 h / 20°C

Filling performance: HYBRID EPOXY PRIMER + HYBRID FILLER HARDENER

The HYBRID EPOXY PRIMER with the HYBRID FILLER HARDENER is intended for the final stage of substrate preparation for the application of paint coats. The primer does not clog sandpaper, which makes it very easy to dry sand for a high quality finish.

PROPERTIES:

- Very good filling performance

- Long pot life for easy priming of the entire vehicle body

- Excellent dry sanding by hand or using power tools

- Very smooth surface

HYBRID EPOXY PRIMER

Innovative combination of the features of epoxy and acrylic primer

ANTI-COROSION / ISOLATOR / FILLER

HYBRID FILLER HARDENER

Hardener for HYBRID EPOXY PRIMER

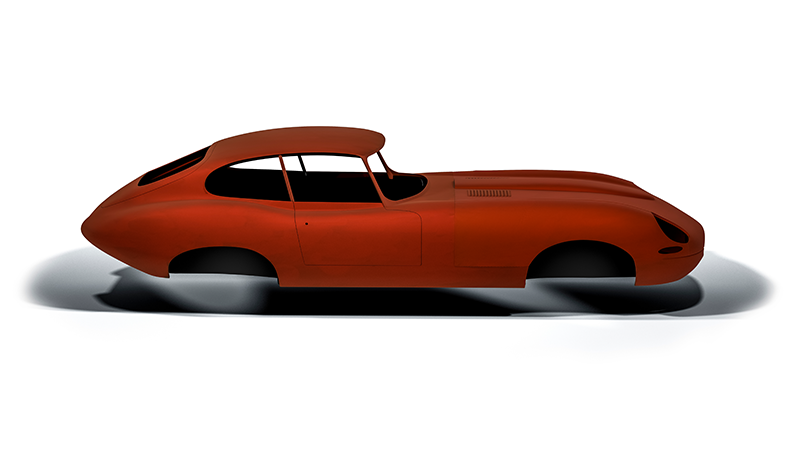

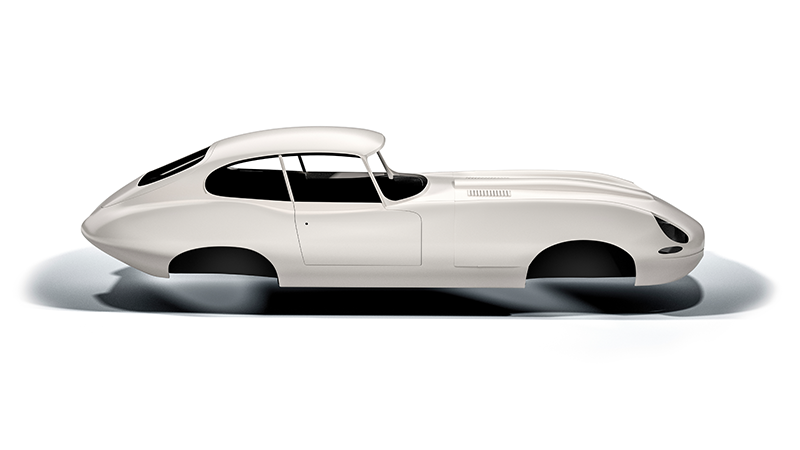

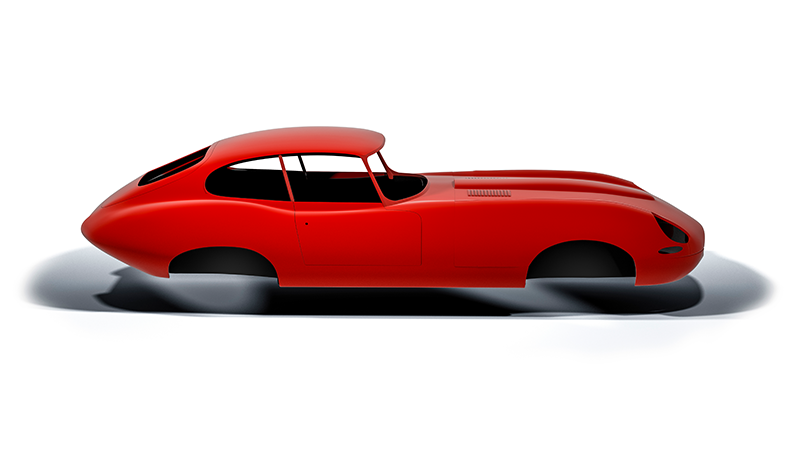

Colour selection

Choosing the correct colours is the most important visual renovation stage. While choosing the colour is discretionary, it largely affects the vehicle value.

This means that colour selection is traditionally limited by the vehicle history, or what the original colour a specific car was manufactured in. These restrictions are predominantly driven by the selling year of a particular model.

Modern environmental protection laws prohibit the use of original materials from the vehicle’s era, while the colour making process relies on formulating a recipe that is as close to the original colour master as possible. The pigmentation capabilities have been greatly improved in recent years, so it is quite possible to reproduce the true colour.

The SPECTRAL Colour System database features thousands of colour tones. The Colour Lab develops more basecoat (thinner-based) and acrylic (2K) recipes from the supplied colour masters.

Water-borne processes are unfit for recoating classic cars, since the resulting coats have weak structures with short life spans.

PREMIUM CSR CLEARCOAT acrylic clearcoat

A superior-quality HS clearcoat with dedicated additives for CSR (coating scratch resistance). The product is easy to apply in all processing conditions and largely irrespective of the painter’s skill level.

It is excellent for multiple recoating, as well as pigmented SPECTRAL 2K (acrylic) + clearcoat PREMIUM-level coating due to the same family of resins and hardeners.

PROPERTIES:

- Crystal gloss and depth

- Innovative coating scratch resistance system (CSR)

- Reduced risk of runs

- Long pot life for whole body coating

- Very high UV resistance

- High solids content

PREMIUM CSR CLEARCOAT

Premium quality for classic vehicles

14h / 20°C

POLYCOAT PROTECT

PROTECTIVE UNDERCOATING OF CHASSIS AND SUSPENSION COMPONENTS

A polyurethane anti-corrosion topcoat with a black, satin finish. The product is intended for protective undercoating of chassis and suspension components. The high thixotropy helps in application in confined areas of the chassis and on complex shapes of suspension parts. The POLYCOAT PROTECT boasts high adhesion and anti-corrosive and elasticising additives.

DUAL PROTECT

PROTECTION OF ROCKER PANELS, WHEEL ARCHES, WELDED SEAMS AND PANEL JOINTS

- Designed for sealing fusion welds and tack welds in classic cars

- Effective protection against damage from water, gasoline, oils, and salt for improved anti-corrosion protection

- Forms a strong, elastic coating with resistance to damage and stone impact

- Sound-proofing and sound-deadening

- Free of asphalt or bitumen compounds, and can be overcoated with all acrylic and polyurethane coats

ML PROTECT

CAVITY PROTECTION

- Anti-corrosive wax & lanolin formula for cavity protection

- Excellent penetration deep into the cracks

- Highly repels moisture from substrates

- A must-have for successful protection of confined parts of the bodywork, like surfaces inside the rocker panels, door brace profiles or body bars

- Penetrates gaps, forming a sealed, hydrophobic coating

STP FLEX

SPRAYABLE SEALANT

- Helps to reproduce various OEM coating textures (from narrow and wide seams to dashed finishes)

- Excellent anti-corrosion protection of fusion welds, tack welds and other seams

- Free of harmful isocyanates: safe for the user’s health, with reduced environmental impact

- Good under thinner or water-based decorative paint coats (no need to sand for up to 10 days before paint coating)

- Correct spray guns and nozzles can reproduce OEM-like seams and textures of motor vehicles

- Fast curing/drying: the skin forms already in 15 min at 20°C

- Excellent sound-deadening performance

- Very good adhesion, strength and elasticity on various substrates

- Odourless

STP FLOW

SPRAYABLE SEALANT

- Helps to reproduce various OEM coating textures (a fine, fuzzy dashed texture that reproduces the rocker panel dashing)

- Excellent anti-corrosion protection of fusion welds, tack welds and other seams

- Free of harmful isocyanates: safe to the user’s health, with reduced environmental impact

- Good under thinner or water-based decorative paint coats (no need to sand for up to 10 days before paint coating)

- Correct spray guns and nozzles can reproduce OEM-like seams and textures for motor vehicles

- Fast curing/drying: Skin forms within 15 min at 20°C

- Excellent sound-deadening performance

- Very good adhesion, strength and elasticity on various substrates

- Odourless

POLYCOAT PROTECT

Anti-corrosion protective coating

24 h / 20°C

DUAL PROTECT

Protection of rocker panels, wheel arches, welded seams and panel joints (2 in 1)

1 h / 20°C

ML PROTECT

Cavity protection

4 h / 20°C

Those car bodies produced in the 1980s and the 1990s require a different renovation process than older vehicles. They are rarely corroded to a point that demands a full bodywork restoration. They most often see the replacement of corroded panel elements; full plating parts, like rocker panels or wheel fenders are replaced with new parts, because they are largely available today.

It is essential to remove old paint coats for a full body refinish. With the coats stripped away, the condition of the sheet steel can be properly assessed while any emerging corrosion can be identified when not visible under the paint coat.

POWER STRIPPING

Power sanding is the best, tested, proven and most popular method of old coating removal. It provides the best control over the stripping process, although it is the most time intensive. Rotary or eccentric sanders are used with coarse grain grit paper or dedicated Nylon pads. In most cases, power stripping is excellent for the removal of incipient corrosion spots. It is good practice to remove old coats in a two-step sanding process: Step one is rough sanding with P60 grit. Step two is finish sanding with P80-P120 grit

ABRASIVE BLASTING

This process is generally recommended for cleaning and stripping:

- Engine compartments

- Boot compartments

- Chassis

- All confined surfaces

With good judgement and the right grit material, this process works well for the removal of old coats from the entire bodies of older vehicles. Youngtimer vehicles feature galvanized/zinc-coated panels which are thinner than those from earlier decades, and are easier to deform by abrasive blasting.

HIGH-PRESSURE WATER CLEANING OF COATINGS

This processing method is gaining popularity and preference, first because it entails no risk of panel deformation or overheating when stripping old paint. Water is used in this process, along with corrosion inhibitors which eliminate the risk of accelerated corrosion. The process leaves the surface fully dry, clean and smooth. Smooth steel needs sanding with a rotary or eccentric tool as well as P80-P120 paper to promote good mechanical adhesion of the layers applied in the later steps of the refinishing process.

Anti-corrosion performance: HYBRID EPOXY PRIMER + HYBRID ANTI-CORROSION HARDENER

The HYBRID EPOXY PRIMER with the HYBRID ANTI-CORROSION HARDENER is intended for preservation of metal substrates, on which the combination forms a sealed coating with high anti-corrosive performance.

This primer provides the proper protection of steel surfaces through the galvanic zinc residues left from cleaning with power tools. The HYBRID EPOXY PRIMER – ANTI-CORROSION has an olive colour and a long chemical activity which allows overcoating with putties or fillers up to 7 days at 20°C without any need for sanding to matt.

PROPERTIES:

- A primer intended for anti-corrosion protection of vehicle bodies made of galvanised/zinc-coated panels

- Long pot life for easy whole-body coating

- Long chemical activity life for overcoating with putties/fillers without sanding to matt for up to 7 days

- Very smooth surface

HYBRID EPOXY PRIMER

Innovative combination of the features of epoxy and acrylic primer

ANTI-COROSION / ISOLATOR / FILLER

HYBRID ANTI-CORROSION HARDENER

Hardener for HYBRID EPOXY PRIMER

BLUE LIGHT lightweight multifunctional body filler

A multifunctional body filler with carefully selected lightweight fillers and resin that provide great convenience when sculpting bodywork parts.

If applied to large work areas in large mixed batches, it is critical to thoroughly mix the polyester resins with the hardener. Otherwise, the decorative paint coat might become discoloured and require refinishing. BLUE LIGHT features the unique Mixing Indicator technology, which shows the polymerisation ratio.

MIXING INDICATOR is a visual reference for your assessment of how thoroughly the filler is mixed with the hardener to avoid component mixing ratio errors. The filler is originally blue, and when mixed with the hardener the colour shifts to grey, and then, when polymerisation ends, the final colour is light beige.

It is natural for polyester fillers to exhibit sedimentation coupled with surfacing of a part of the resin and the dye. It is perfectly normal and common to this type of product. It is always necessary to homogenize the product by stirring it in the container before mixing with the hardener.

PROPERTIES:

- Very easy rough and finish processing

- Perfect for sculpting shapes on large work areas

- The safe Mixing Indicator technology ensures perfect mixing of the components

- Creamy texture for easy application

- Very low volumetric shrinkage, thanks to spherical fillers

BLUE LIGHT

Light and multi-functional

30 min / 20°C

Insulation performance: HYBRID EPOXY PRIMER + HYBRID ISOLATOR HARDENER

HYBRID EPOXY PRIMER with HYBRID ANTI-CORROSION HARDENER is intended for preservation of metal substrates, on which the combination forms a sealed coating with high anti-corrosive performance. The thin-coat primer protects against the absorption of solvents and potential moisture during pretreatment for the application of decorative coatings. This product is recommended in the entire refinishing process for isolating over-sanded spots (exposing bare metal). It is suitable for wet-on-wet application.

PROPERTIES:

- Quick-drying epoxy primer

- Perfect for anti-corrosion protection and isolation of spots sanded to bare metal

- Excellent protection against thinners and moisture

- Very smooth texture for easy wet-on-wet application

HYBRID EPOXY PRIMER

Innovative combination of the features of epoxy and acrylic primer

ANTI-COROSION / ISOLATOR / FILLER

HYBRID ANTI-CORROSION HARDENER

Hardener for HYBRID EPOXY PRIMER

P-S spray filler

A polyester spray filler with the colour-shift based Mixing Indicator for the polymerisation ratio.

The P-S spray filler is a finish filler for the final stage of surface sculpting. The filler reduces sagging and isolates earlier layers of a filler mixed with the hardener at an incorrect ratio.

The special selection of fillers and resins minimises shrinkage to 5%, providing excellent processability on large work areas. Further processing of the product layer is recommended after a minimum of 12–16 h at 20°C.

MIXING INDICATOR is a visual reference for your assessment of how thoroughly the filler is mixed with the hardener to avoid component mixing ratio errors. The filler is originally sharp blue, then when mixed with the hardener the colour shifts to grey blue and, when polymerisation ends, the final colour is white.

It is natural for polyester fillers to exhibit sedimentation coupled with surfacing of a part of the resin and the dye. It is perfectly normal and common to this type of product. It is always necessary to homogenize the product by stirring it in the container before mixing with the hardener.

PROPERTIES:

- Produces a smooth surface on large work areas

- Quick and easy application from a Ø2.5 mm spray gun

- Safe to apply in thick layers (up to 300 µm) without sagging

- Mixing Indicator becomes active already during mixing, ensuring good assessment of the correct component blending

- Can be thinned further (up to 10% vol.)

P-S

Spray for final sculpting of work surfaces

3 h / 20°C

Filling performance: HYBRID EPOXY PRIMER + HYBRID FILLER HARDENER

HYBRID EPOXY PRIMER with HYBRID FILLER HARDENER is intended for the final stage of substrate preparation for the application of paint coats. The primer does not clog sandpaper, which makes it very easy to dry sand for a high quality finish.

PROPERTIES:

- Very good filling performance

- Long pot life for easy priming of the entire vehicle body

- Excellent dry sanding by hand or power tools

- Very smooth surface

HYBRID EPOXY PRIMER

Innovative combination of the features of epoxy and acrylic primer

ANTI-COROSION / ISOLATOR / FILLER

HYBRID FILLER HARDENER

Hardener for HYBRID EPOXY PRIMER

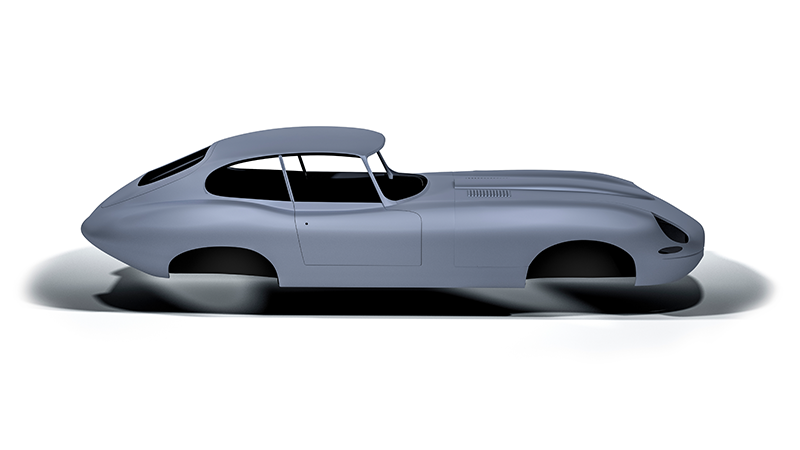

Colour selection

For most youngtimer vehicles, the OEM colour is secondary. Considering the visual qualities, a colour from a different panel is selected and pigmented to match the permitted tuning features. An exception is partial refinishing where the existing coating demands a spot repair and the right shade of the colour must be formulated.

All car bodies from the 1980s are easy to refinish with a basecoat from the SPECTRAL WAVE 2.0 water-based system, which features hundreds of recipes for colour coating with special effects.

SPECTRAL WAVE 2.0 is a second generation water-based coating system which provides much higher hardness and ease of application for projects that have whole car bodies spray-coated in booths that may vary in ventilation air flow rate.

PREMIUM FLOW CLEARCOAT acrylic clearcoat

The highest quality VHS class polyurethane clearcoat, with a very high gloss and hardness, designed for refinishing of classic motor vehicles.

PREMIUM FLOW CLEARCOAT features enhanced levelling for the maximum durability of the colour and high gloss in two-layer applications. The long pot life makes it easy to coat whole car bodies, even in spray booths where the ambient air flow is limited. It is excellent for multiple recoating, as well as pigmented SPECTRAL 2K (acrylic) + clearcoat PREMIUM-level coating due to the same family of resins and hardeners.

PROPERTIES:

- Crystal gloss and depth

- High final hardness thanks to the innovative urethane resin

- Perfect levelling

- Good yield

- Very high UV resistance

- Long pot life for whole body coating

- Very high solids content

PREMIUM FLOW CLEARCOAT

Acrylic-urethane VHS with high gloss

12h / 20°C

POLYCOAT PROTECT

PROTECTIVE UNDERCOATING OF CHASSIS AND SUSPENSION COMPONENTS

A polyurethane anti-corrosion topcoat with a black, satin finish. The product is intended for protective undercoating of chassis and suspension components. The high thixotropy helps in application in confined areas of the chassis and on complex shapes of suspension parts. POLYCOAT PROTECT boasts high adhesion and anti-corrosive and elasticising additives.

DUAL PROTECT

PROTECTION OF ROCKER PANELS, WHEEL ARCHES, WELDED SEAMS AND PANEL JOINTS

- Designed for sealing fusion welds and tack welds in classic cars

- Effective protection against damage from water, gasoline, oils, and salt, for improved anti-corrosion protection

- Forms a strong, elastic coating with resistance to damage and stone impact

- Sound-proofing and sound-deadening

- Free of asphalt or bitumen compounds, and can be overcoated with all acrylic and polyurethane coats

ML PROTECT

CAVITY PROTECTION

- Anti-corrosive wax & lanolin formula for cavity protection

- Excellent penetration, deep into the cracks

- Highly repels moisture from substrates

- A must-have for successful protection of confined parts of the bodywork, like surfaces inside the rocker panels, door brace profiles or body bars

- Penetrates gaps, forming a sealed, hydrophobic coating

STP FLEX

SPRAYABLE SEALANT

- Helps to reproduce various OEM coating textures (from narrow and wide seams to dashed finishes)

- Excellent anti-corrosion protection of fusion welds, tack welds and other seams

- Free of harmful isocyanates: safe to the user’s health, with reduced environmental impact

- Good under thinner or water-based decorative paint coats (no need to sand for up to 10 days before paint coating)

- Correct spray guns and nozzles can reproduce OEM-like seams and textures of motor vehicles

- Fast curing/drying: the skin forms already in 15 min at 20°C

- Excellent sound-deadening performance

- Very good adhesion, strength and elasticity on various substrates

- Odourless

STP FLOW

SPRAYABLE SEALANT

- Helps to reproduce various OEM coating textures (a fine, fuzzy dashed texture that reproduces the rocker panel dashing)

- Excellent anti-corrosion protection of fusion welds, tack welds and other seams

- Free of harmful isocyanates: safe to the user’s health, with reduced environmental impact

- Good under thinner or water-based decorative paint coats (no need to sand for up to 10 days before paint coating)

- Correct spray guns and nozzles can reproduce OEM-like seams and textures of motor vehicles

- Fast curing/drying: Skin forms within 15 min at 20°C

- Excellent sound-deadening performance

- Very good adhesion, strength and elasticity on various substrates

- Odourless

POLYCOAT PROTECT

Anti-corrosion protective coating

24 h / 20°C

DUAL PROTECT

Protection of rocker panels, wheel arches, welded seams and panel joints (2 in 1)

1 h / 20°C

ML PROTECT

Cavity protection

4 h / 20°C

Polski

Polski  Русский

Русский  Deutsch

Deutsch  Español

Español  Français

Français  Українська

Українська  Ελληνικά

Ελληνικά