NOVOL RESEARCH & DEVELOPMENT LABORATORY

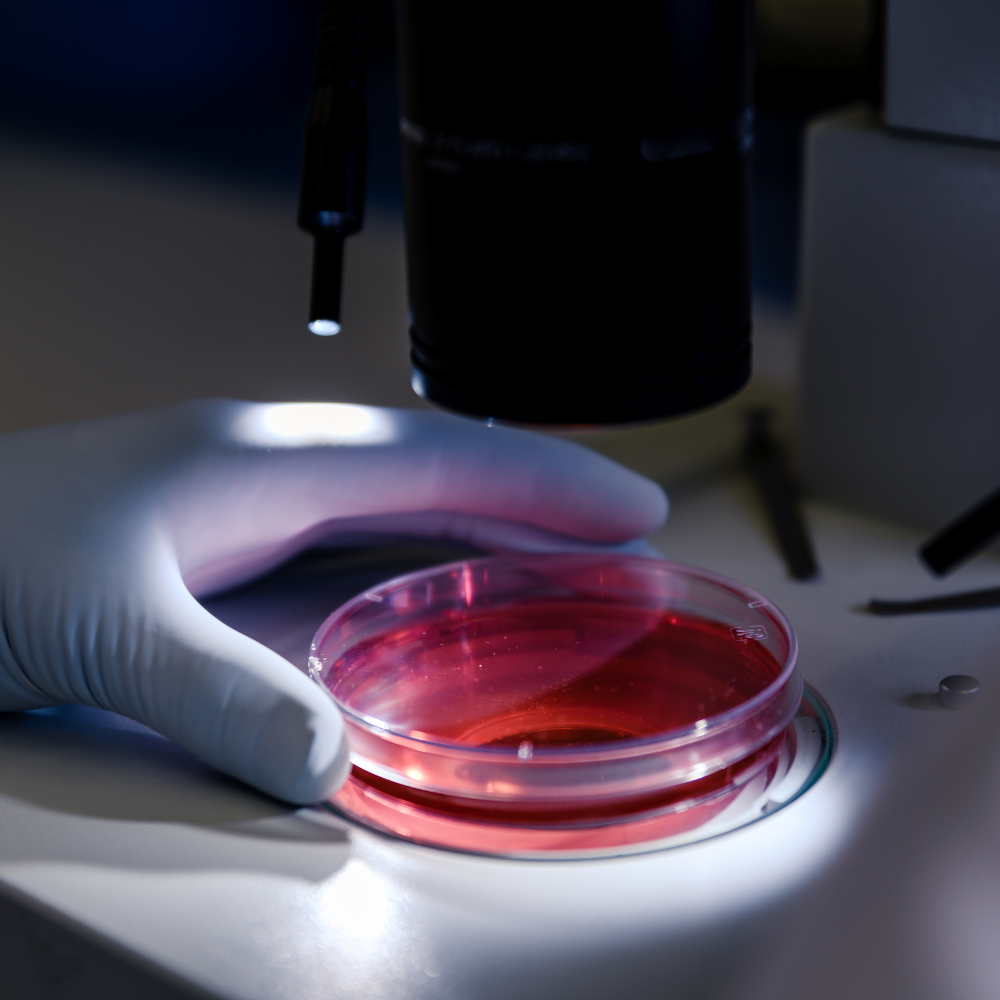

NOVOL has its own Research & Development Laboratory, a modern advanced unit which has been incessantly on the search for innovative solutions. It is staffed by a team of qualified and experienced specialists who undertake the testing in automotive and industrial coatings and boatbuilding chemicals.

Their research includes the development of recipes for products and their manufacture processing, mechanical testing (for tensile strength, bending, shearing, impact resistance, hardness , etc.), ageing and weathering testing (anti-corrosion tests in a spray salt chamber, UV resistance tests, etc.), and evaluation of application parameters and performance (adhesion to different types of substrates, penetrating power, filling/build, texture, gloss level etc.).

All Novol products are manufactured from high-quality materials in modern and controlled processes. Novol’s Quality Management System conforms to ISO 9001:2015. With the QMS in place, Novol can guarantee that the products you receive always have the same performance and efficiency. The entire production process is supervised by the internal Process Engineering Laboratory, which verifies compliance of the products coming from the production line with the required quality standards.

Polski

Polski  Русский

Русский  Deutsch

Deutsch  Français

Français  Ελληνικά

Ελληνικά  Українська

Українська