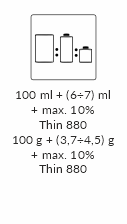

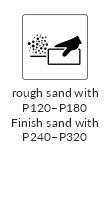

Polyester spray filler

A polyester spray filler with the colour-shift based Mixing Indicator of polymerisation ratio. The P-S spray filler is a finish filler for the last stage of surface sculpting. The filler reduces sagging and isolates earlier layers of a filler mixed with the hardener at an incorrect ratio. The special selection of fillers and resins minimises shrinkage to 5%, providing excellent processability on large work areas. Further processing of the product’s layer is recommended after a minimum of 12–16 h at 20°C. Mixing Indicator is a visual reference for your assessment of how thoroughly the filler is mixed with the hardener to avoid component mixing ratio errors. The filler is originally sharp blue, then when mixed with the hardener the colour shifts to grey blue and, when polymerisation ends, the final colour is white.

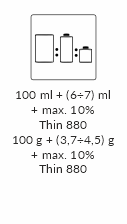

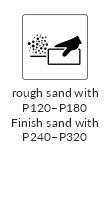

Polyester spray filler with aluminium dust

A polyester spray filler with aluminium dust applied during the process of adapting the coating to high temperature changes (from the engine heat under a cold bonnet and in cars finished in dark colours). The specifically engineered formula contains the same aluminium fillers as the ALUMINIUM filler, ensuring that the application of both products provide the same thermal conductivity levels.